Get unique, complex parts easily. No matter your requirements, Master Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Master Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Uncategorized | August 23, 2016

Direction wind is one of the first steps in setting up springs – after all, every spring is either wound to the right or left. But what’s the difference, and does it really matter?

The short answer is yes, it absolutely matters. While the direction of the wind won’t change the price of a spring, it can impact the overall functionality. Therefore, it’s sometimes important to specify the wind direction instead of leaving it up to the operator’s discretion.

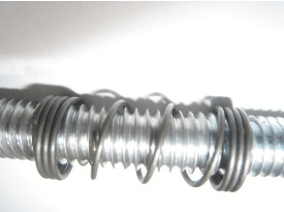

Compression Springs: If you are screwing a compression spring onto a mating part, you would want the coil direction to matc h that of the threads. Sometimes, though, you wouldn’t want the pitch of the spring to get caught up in the pitch of the threaded mating part. An example would be a spring working over a threaded bolt. In this case you would want an opposite coil/thread relationship.

h that of the threads. Sometimes, though, you wouldn’t want the pitch of the spring to get caught up in the pitch of the threaded mating part. An example would be a spring working over a threaded bolt. In this case you would want an opposite coil/thread relationship.

Torsion Springs: When deflected, the torsion legs should always move inward towards each other thus tightening up the coil diameter, making it smaller. Make sure the wind of the torque spring you’re trying to apply reflects this.

Torsion Springs: When deflected, the torsion legs should always move inward towards each other thus tightening up the coil diameter, making it smaller. Make sure the wind of the torque spring you’re trying to apply reflects this.

Extension Springs: Coil direction can be important for extension springs if the coils are screwing onto a mating part. In this case you would want the coil direction to match that of the threads. Typically, this would be right hand wound (RHW). A change in coil direction can also help if you are trying to locate hook gaps in a certain position.

While you typically don’t want to be staring down barrels, as old sayings go, the direction wind of a coil can be determined by looking down into the barrel of the spring. Position the spring’s cutoff so that it is pointing away from you (see below).

If the cutoff/torsion end is on the left hand side of the spring (9 o’clock position), then the spring is LHW. Alternatively, if the cutoff/torsion end is on the right hand side of the spring (3 o’clock position), then the spring is RHW.